Plastic pollution is a major concern for many in Canada and around the world, including students and researchers at the University of British Columbia, where budding ventures are hustling hard on creative solutions to local and global issues.

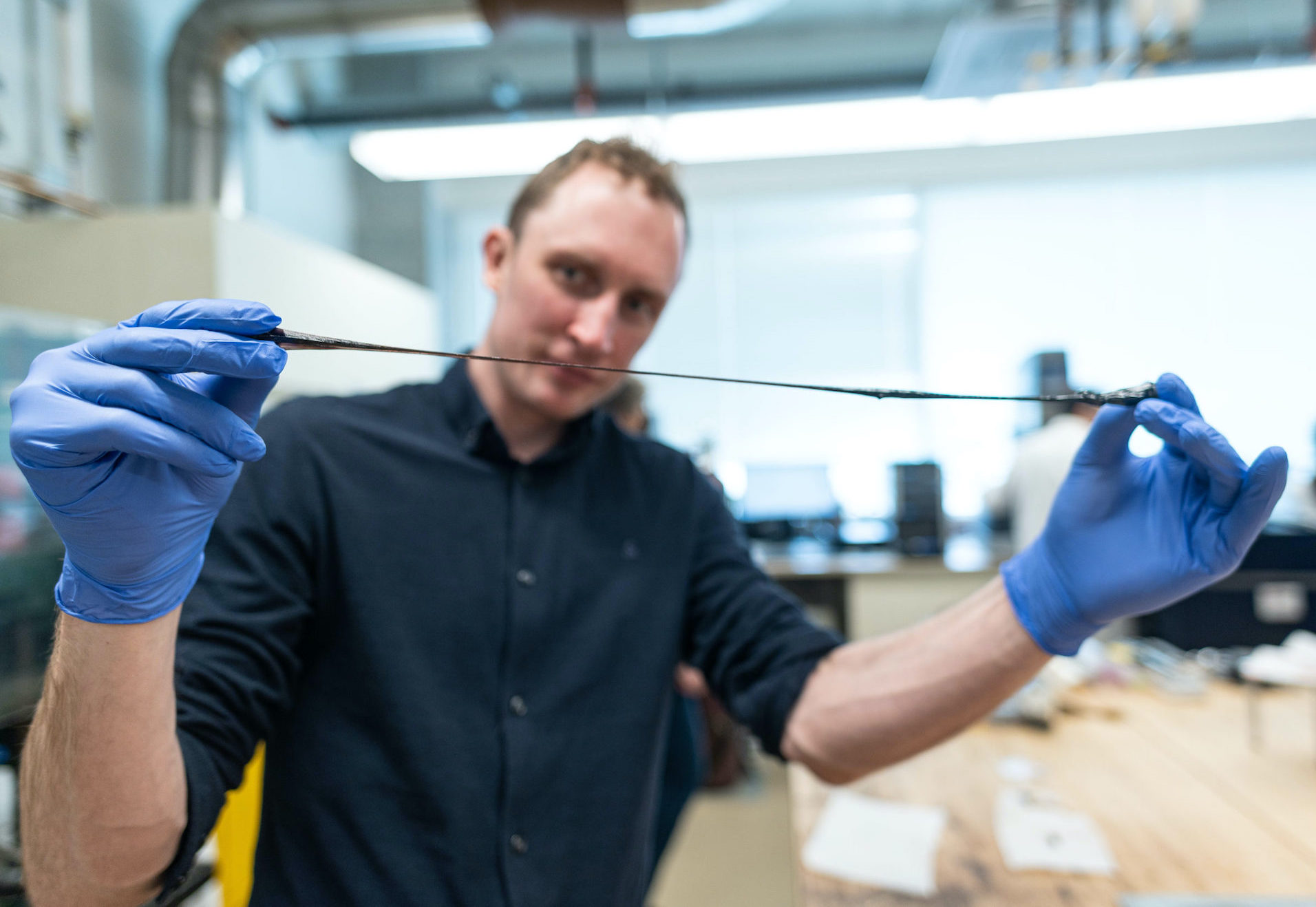

One of these ventures is A2O Advanced Materials. The UBC startup is testing a class of novel polymers that, when added to other products like marine paints and industrial coatings, can make them self-healing and weather-resistant—increasing their lifespan.

A20 describes itself as a “materials innovation company dedicated to transforming industries and facilitating their transition to a clean economy” using breakthrough technology.

What makes their polymer unique, A20 notes, is that it has been enhanced using a patented process. The polymer can rebuild itself when it is torn and scratched.

“You could almost call these materials alive,” posits A2O co-founder Dr. Damon Gilmour. “They have the ability to respond to stimuli and are self-healing.”

The BC company is currently scaling its technology through pilot projects designed to address big environmental problems in industry, including biofouling, corrosion, and textile waste.

“We’re looking to deploy those materials in global industries such as shipping, energy and textiles, where the ability of the materials to self-heal or respond to external stressors means the product can last longer and work more efficiently,” explains Gilmour.

Self-healing materials have drawn attention from battery manufacturers looking to extend the lifespan of phones and energy storage devices. Given the uniqueness of A20’s material, the applications are potentially infinite.

“These unique materials possess a plethora of remarkable properties such as reversibility, flexibility, self-healing, adhesion, biocompatibility, thermal stability, anticorrosion and antimicrobial activity all at once—a combination that cannot be found in another class of polymeric materials,” chemical and biological engineering professor Dr. Savvas Hatzikiriakosm, a cofounder of A20, affirmed.

Another UBC venture tackling plastic pollution is Bioform Technologies, which has developed a process for turning abundant kelp and wood fibre into functional plastics that can replace commonly polluted items such as food containers and beverage lids.

Since 2013, entrepreneurship@UBC has mobilized entrepreneurship, helping the UBC community translate innovation into tangible impact through the creation of transformative ventures.

Terrific work, just thinking about some uses such as on pipeline coatings for underground and river crossing. The environmental benefits are staggering!